NATIONAL INSTITUTE OF INDUSTRIAL

ENGINEERING

Component: Spring

By

Abhinav Jaiswal, 2

Ashish Tomar, 20

Introduction

Spring is defined as an elastic body, whose function is to

distort when loaded and to recover to its original shape when the load is

removed.

Objectives of Spring

Following are the objectives of a spring when used as a

machine member:

1. Cushioning, absorbing, or controlling of energy due to

shock and vibration.

Car springs or railway buffers

To control energy, springs-supports and vibration dampers.

2. Control of motion

Maintaining contact between two elements (cam and its follower)

In a cam and a follower arrangement, widely used in numerous

applications, a spring maintains contact between the two elements. It primarily

controls the motion.

Creation of the necessary pressure in a friction device (a brake

or a clutch)

A person driving a car uses a brake or a clutch for controlling

the car motion. A spring system keep the brake in disengaged position until

applied to stop the car. The clutch has also got a spring system (single

springs or multiple springs) which engages and disengages the engine with the

transmission system.

Restoration of a machine part to its normal position when the

applied force is withdrawn (a governor or valve)

A typical example is a governor for turbine speed control. A

governor system uses a spring controlled valve to regulate flow of fluid

through the turbine, thereby controlling the turbine speed.

3. Measuring forces

Spring balances, gages

4. Storing of energy

In

clocks or starters

The

clock has spiral type of spring which is wound to coil and then the stored

energy helps gradual recoil of the spring when in operation. Nowadays we do not

find much use of the winding clocks.

Before considering the design aspects of springs we will have a quick

look at the spring materials and manufacturing methods.

Commonly used spring materials

One of the important considerations in spring design is the choice of

the spring material. Some of the common spring materials are given below.

·

Hard-drawn wire:

This

is cold drawn, cheapest spring steel. Normally used for low stress and static

load. The material is not suitable at subzero temperatures or at temperatures

above 1200C.

·

Oil-tempered wire:

It is

a cold drawn, quenched, tempered, and general purpose spring steel. However, it

is not suitable for fatigue or sudden loads, at subzero temperatures and at

temperatures above 1800C.

When

we go for highly stressed conditions then alloy steels are useful.

·

Chrome Vanadium:

This

alloy spring steel is used for high stress conditions and at high temperature

up to 2200C. It is good for fatigue resistance and long endurance for shock and

impact loads.

·

Chrome Silicon:

This

material can be used for highly stressed springs. It offers excellent service

for long life, shock loading and for temperature up to 2500C.

·

Music wire:

This

spring material is most widely used for small springs. It is the toughest and

has highest tensile strength and can withstand repeated loading at high

stresses. However, it cannot be used at subzero temperatures or at temperatures

above 1200C.

Normally

when we talk about springs we will find that the music wire is a common choice

for springs.

·

Stainless steel:

Widely

used alloy spring materials.

·

Phosphor Bronze /

Spring Brass:

It has

good corrosion resistance and electrical conductivity. That’s the reason it is

commonly used for contacts in electrical switches. Spring brass can be used at

subzero temperatures.

Spring manufacturing processes

If springs are of very small diameter and the wire diameter is also

small then the springs are normally manufactured by a cold drawn process

through a mangle. However, for very large springs having also large coil

diameter and wire diameter one has to go for manufacture by hot processes.

First one has to heat the wire and then use a proper mangle to wind the coils.

Helical spring

The figures below show the schematic representation of a helical spring

acted upon by a tensile load F (Fig.7.1.1) and compressive load F (Fig.7.1.2).

The circles denote the cross section of the spring wire. The cut section, i.e.

from the entire coil somewhere we make a cut, is indicated as a circle with

shade.

If we look at the free body diagram of the shaded region

only (the cut section) then we shall see that at the cut section, vertical

equilibrium of forces will give us force, F as indicated in the figure. This F

is the shear force. The torque T, at the cut section and it’s direction is also

marked in the figure. There is no horizontal force coming into the picture

because externally there is no horizontal force present. So from the

fundamental understanding of the free body diagram one can see that any section

of the spring is experiencing a torque and a force. Shear force will always be

associated with a bending moment.

However, in an ideal situation, when force is acting at the

centre of the circular spring and the coils of spring are almost parallel to each

other, no bending moment would result at any section of the spring (no moment

arm), except torsion and shear force. The Fig.7.1.3 will explain the fact

stated above.

Stresses in the helical spring wire:

From the free body diagram, we have found out the direction of the

internal torsion T and internal shear force F at the section due to the

external load F acting at the centre of the coil.

The cut sections of the spring, subjected to tensile and compressive

loads respectively, are shown separately in the Fig.7.1.4 and 7.1.5. The broken

arrows show the shear stresses ( τT ) arising due to the

torsion T and solid arrows show the shear stresses ( τF ) due

to the force F. It is observed that for both tensile load as well as

compressive load on the spring, maximum shear stress (τT + τF)

always occurs at the inner side of the spring. Hence, failure of the spring, in

the form of crake, is always initiated from the inner radius of the spring.

The radius of the spring is given by D/2. Note that D is the

mean diameter of the spring.

The torque T acting on the

spring is

(7.1.1)

If d is the diameter of the

coil wire, then polar moment of inertia,

The shear stress in the spring wire

due to torsion is

(7.1.3)

Average shear stress in the spring wire due to force F is

(7.1.3)

Therefore, maximum shear

stress the spring wire is

(7.1.4)

The above equation gives maximum shear stress occurring in a

spring. Ks

is the shear stress correction factor.

Stresses in helical spring with curvature effect:

What is curvature effect?

Let us look at a small section of a circular spring, as shown in the Fig.7.1.6.

Suppose we hold the section b-c fixed and give a rotation to the section a-d in

the anti clockwise direction as indicated in the figure, then it is observed

that line a-d rotates and it takes up another position, say a'-d'. The inner

length a-b being smaller compared to the outer length c-d, the shear strain γi at the

inside of the spring will be more than the shear strain γo at the

outside of the spring. Hence, for a given wire diameter, a spring with smaller

diameter will experience more difference of shear strain between outside

surface and inside surface compared to its larger counterpart. The above

phenomenon is termed as curvature effect. So more is the spring index (C=D/d) the lesser will be the

curvature effect. For example, the suspensions in the railway carriages use

helical springs. These springs have large wire diameter compared to the

diameter of the spring itself. In this case curvature effect will be

predominantly high.

To take care of the curvature effect, the earlier equation

for maximum shear stress in the spring wire is modified as,

Where, KW is Wahl correction factor, which

takes care of both curvature effect and shear stress correction factor and is

expressed as,

Deflection of helical spring:

Consider a small segment of spring of length ds, subtending an

angle of dβ at the center of the spring coil as shown in Fig.7.1.7(b). Let this

small spring segment be considered to be an active portion and remaining

portion is rigid. Hence, we consider only the deflection of spring arising due

to application of force F. The rotation, dφ, of the section a-d with respect to

b-c is given as,

The rotation, dφ will cause the end of the spring O to

rotate to O', shown in Fig. 7.1.7(a). From geometry, O-O' is given as,

However, the vertical component of O-O' only will

contributes towards spring deflection. Due to symmetric condition, there is no

lateral deflection of spring, ie, the horizontal component of O-O' gets

cancelled.

The vertical component of

O-O', dδ, is given as,

Total deflection of spring, δ, can be obtained by

integrating the above expression for entire length of the spring wire.

Simplifying the above expression we get,

Where, N is

the number of active turns and G is the shear modulus of elasticity. Now

what is an active coil? The force F cannot just hang in space, it has to have

some material contact with the spring. Normally the same spring wire e will be

given a shape of a hook to support the force F. The hook etc., although is a

part of the spring, they do not contribute to the deflection of the spring.

Apart from these coils, other coils which take part in imparting deflection to

the spring are known as active coils.

The above equation is used to compute the deflection of a helical

spring. Another important design parameter often used is the spring rate. It is

defined as,

Design of helical spring for variable load

In the case of a spring, whether it is a compression spring or an

extension spring, reverse loading is not possible. For example, let us consider

a compression spring placed between two plates. The spring under varying load

can be compressed to some maximum value and at the most can return to zero

compression state (in practice, some amount of initial compression is always

present), otherwise, spring will loose contact with the plates and will get

displace from its seat. Similar reason holds good for an extension spring, it

will experience certain amount of extension and again return to at the most to

zero extension state, but it will never go to compression zone. Due to varying

load, the stress pattern which occurs in a spring with respect to time is shown

in Fig.7.2.1. The load which causes such stress pattern is called repeated

load. The spring materials, instead of testing under reversed bending, are

tested under repeated torsion.

From Fig.7.2.1 we see that,

(7.2.1)

Where, τa is known as the stress amplitude and τm is

known as the mean stress or the average stress. We know that for varying

stress, the material can withstand stress not exceeding endurance limit value.

Hence, for repeated torsion experiment, the mean stress and the stress

amplitude become,

(7.2.2)

Soderberg

failure criterion:

The

modified Soderberg diagram for repeated stress is shown in the Fig 7.2.2.

The stress being repeated in nature, the

co-ordinate of the point a is ( τe/2,

τe/2). For safe design, the design data for the mean and average stresses,

τa and

τm respectively, should

be below the line a-b. If we choose a value of factor of safety (FS), the line

a-b shifts to a newer position as shown in the figure. This line e-f in the

figure is called a safe stress line and the point A (τm, τa) is a

typical safe design point.

Considering

two similar triangles, abc and Aed respectively, a relationship

between the stresses may be developed and is given as,

(7.2.3)

where τY is the shear yield point of the spring

material.

In simplified form, the

equation for Soderberg failure criterion for springs is

(7.2.4)

The above equation is further modified by considering the shear

correction factor, Ks and Wahl correction factor, Kw. It is

a normal practice to multiply τm by Ks and to multiply τa by Kw.

(7.2.5)

The above equation for Soderberg failure criterion for will

be utilized for the designing of springs subjected to variable load.

Estimation of material strength

It is a very important aspect in any design to obtain

correct material property. The best way is to perform an experiment with the

specimen of desired material. Tensile test experiments as we know is relatively

simple and less time consuming. This experiment is used to obtain yield

strength and ultimate strength of any given material. However, tests to

determine endurance limit is extremely time consuming. Hence, the ways to

obtain material properties is to consult design data book or to use available

relationships, developed through experiments, between various material

properties. For the design of springs, we will discuss briefly, the steps

normally used to obtain the material properties.

One of the relationships to find out ultimate strength of a

spring wire of diameter d is,

(7.2.6)

For some selected materials, which are commonly used in spring

design, the values of As and ms are given in the table below.

The above

formula gives the value of ultimate stress in MPa for wire diameter in mm. Once

the value of ultimate strength is estimated, the shear yield strength and shear

endurance limit can be obtained from the following table developed through

experiments for repeated load.

Hence, as a rough guideline and on a conservative side, values for

shear yield point and shear endurance limit for major types of spring wires can

be obtained from ultimate strength as,

(7.2.7)

With the knowledge of material properties and load

requirements, one can easily utilize Soderberg equation to obtain spring design

parameters.

Types of springs

There are mainly two types of helical springs, compression springs

and extension springs. Here we will have a brief look at the types of springs

and their nomenclature.

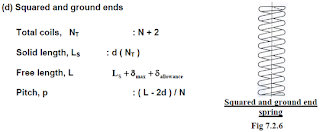

1. Compression springs

Following

are the types of compression springs used in the design.

Solid length, LS is that length of the

spring, when pressed, all the spring coils will clash with each other and will

appear as a solid cylindrical body.

The spring length under no load condition is the free length

of a spring. Naturally, the length that we visualise in the above diagram is

the free length.

Maximum amount of

compression the spring can have is denoted as δmax , which is calculated from the

design requirement. The addition of solid length and the δmax should

be sufficient to get the free length of a spring. However, designers consider

an additional length given as δallowance. This allowance is provided to

avoid clash between to consecutive spring coils. As a guideline, the value of δallowance is

generally 15% of δmax.

The concept of pitch in a spring is the same as that in a screw.

The top and bottom of the spring is grounded

as seen in the figure. Here, due to grounding, one total coil is inactive.

In the Fig

7.2.5 it is observed that both the top as well as the bottom spring is being

pressed to make it parallel to the ground instead of having a helix angle.

Here, it is seen that two full coils are inactive.

It is

observed that both the top as well as the bottom spring, as earlier one, is

being pressed to make it parallel to the ground, further the faces are grounded

to allow for proper seat. Here also two full coils are inactive.

2. Extension

springs

Part of an extension spring with a hook is shown in

Fig.7.2.7. The nomenclature for the extension spring is given below.

Body

length, LB: d (N + 1)

Free

length, L : LB + 2 hook diameter.

here, N stands for the number of active coils. By putting

the hook certain amount of stress concentration comes in the bent zone of the

hook and these are substantially weaker zones than the other part of the

spring. One should take up steps so that stress concentration in this region is

reduced. For the reduction of stress concentration at the hook some of the

modifications of spring are shown in Fig 7.2.8.

Buckling of compression spring

Buckling is an instability that is normally shown up when a long

bar or a column is applied with compressive type of load. Similar situation

arise if a spring is too slender and long then it sways sideways and the

failure is known as buckling failure. Buckling takes place for a compressive

type of springs. Hence, the steps to be followed in design to avoid buckling

are given below.

Free

length (L) should be less than 4 times the coil diameter (D) to avoid buckling

for most situations. For slender springs central guide rod is necessary.

A guideline

for free length (L) of a spring to avoid buckling is as follows,

For

steel,

Where, Ce is

the end condition and its values are given below

Ce End condition

2.0 fixed and free

end

1.0 hinged at both

ends

0.707 hinged and fixed end

0.5 fixed at both ends

If the

spring is placed between two rigid plates, then end condition may be taken as

0.5. If after calculation it is found that the spring is likely to

buckle then one has to use a guide rod passing through the center of the spring

axis along which the compression action of the spring takes place.

Spring surge (critical frequency)

If a load F act on a spring there is a downward movement of

the spring and due to this movement a wave travels along the spring in downward

direction and a to and fro motion continues. This phenomenon can also be

observed in closed water body where a disturbance moves toward the wall and

then again returns back to the starting of the disturbance. This particular

situation is called surge of spring. If the frequency of surging becomes equal

to the natural frequency of the spring the resonant frequency will occur which

may cause failure of the spring. Hence, one has to calculate natural frequency,

known as the fundamental frequency of the spring and use a judgment to specify

the operational frequency of the spring.

The fundamental frequency can be obtained from the

relationship given below.

Fundamental

frequency :

Both ends within

flat plates (7.2.9)

One

end free and other end on flat plate. (7.2.10)

Where,

K: Spring rate

WS : Spring weight = 2.47γd2DN

and d is

the wire diameter, D is the coil diameter, N is the number of

active coils and γ is the specific weight of spring material.

The

operational frequency of the spring should be at least 15-20 times less than

its fundamental frequency. This will ensure that the spring surge will not

occur and even other higher modes of frequency can also be taken care of.

Spring Manufacturing Process

I have read your blog information. Its very detailed nice information. your information very useful for me. Thanks for sharing such a nice blog post.

ReplyDeleteTorsion springs

Hi,

ReplyDeleteYour blog is really contains awesome stuff about various types of wires & spring, i really liked your blog because of in-dept information about spring.

Mahesh

Spring Wire Manufacturers In India

Thanks, for such a great post. I have tried and found it really helpful. For more details to visit Heavy duty compression springs

ReplyDeleteI have read your article, this is really nice and explain in Details. Thanks for sharing this informative articles.

ReplyDeleteTorsion Springs

Compression Springs