Optimization of Steel Helical Spring by

Composite Spring

Journal: International

Journal of Multidisciplinary Sciences and Engineering, Vol. 3, No. 6, June 2012

Author:

Mehdi Bakhshesh and Majid Bakhshesh

Summary by:

Abhinav Jaiswal, 2

PGDIE 42

Abstract:

Springs that can reserve high level of

potential energy, have undeniable role in industries. Helical spring is the

most common element that has been used in car suspension system. In this research,

steel helical spring

related to light

vehicle suspension system under the effect of a uniform loading has been

studied and finite element analysis has been compared with analytical solution.

Afterwards, steel spring has been replaced by three different composite helical

springs including E-glass/Epoxy, Carbon/Epoxy and Kevlar/Epoxy. Spring

weight, maximum stress and deflection have been compared with steel

helical spring and factors of safety under the effect of applied loads have

been calculated. It has been shown that spring optimization by material

spring changing causes reduction of spring weight and maximum stress

considerably. In any case, with changing fiber angle relative to spring axial,

composite spring properties have been investigated.

Introduction

Helical springs are simple forms of springs,

commonly used for the suspension system in wheeled vehicles. Vehicle suspension

system is made out of springs that have basic role in power transfer, vehicle

motion and driving. Therefore, springs performance optimization plays important

role in improvement of car dynamic. The automobile industry tends to improve

the comfort of user and reach appropriate balance of comfort riding qualities

and economy. There is increased interest in the replacement of steel helical

spring with composite helical spring due to high strength to weight ratio. On

the other hand, there is a limitation at the amount of applied loads in

springs. The increase in applied load makes problem at geometrical alignment of

car height and erodes other parts of car. So, springs design in point of

strength and durability is very important. Reduction of spring weight is also

principal parameter in improvement of car dynamic. By replacement of steel

helical spring with composite helical spring will reduce spring weight in

addition to resistance raise under the effect of applied loads. In this research, a static analysis is

employed to investigate behaviour of steel and composite helical spring related

to light vehicle suspension system. Steel spring has been replaced by three

different composite helical in ANSYS software and results have been compared

with analytical solution. The objective is to compare the load carrying capacity, stiffness and weight savings of composite

helical spring with

that of steel

helical spring.

Advanced composite fibers such as glass,

carbon and Kevlar- reinforced suitable resins, are expected to be widely used

in vehicle suspension system

application so that

spring of different shapes

can be obtained.

This refers to the high specific strength (strength-to-density ratio)

and high specific modules (modules-to-density ratio) of this advanced composite

materials. The method used for the production of the springs is a variation of

the RTM (Resin Transfer Molding) process. Through this method, the dry braids

are positioned in the mold before being impregnated with the resin, making

production very clean. In this case, an open mold consisting of a helically

grooved mandrel is used, and the braids are impregnated by plunging in a bowl

filled with resin.

Many studies are carried out to investigate

the behaviour of composite springs. Senthil Kumart and Vijayarangan

investigated behaviour of composite leaf spring for light passenger vehicles.

Compared to steel spring, the composite leaf spring was found to have lesser

stress, higher stiffness and higher natural frequency than that of existing

steel leaf spring and weight of spring was reduced by using optimized composite

leaf spring. They also concluded that fatigue life of composite leaf spring was

more than that of conventional steel leaf spring.

Solid Modeling of

Metal Helical Spring

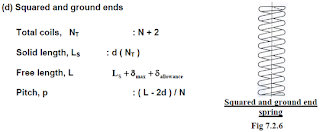

Helical springs have the characteristic

parameters that affect their behaviours. In addition to the physical properties

of its material, the wire diameter (d), loop diameter (D), number of loops (Na)

and the distance between two consecutive loops (P) are the parameters that

affect the behaviour of spring. These parameters have been illustrated in Fig. below:

Before analysis of helical spring, the rate of spring, shear

modulus and poison coefficient are needed to be calculated.

Simulation of

Steel Helical Spring

Spring Geometry is modeled

in SOLIDWORKS software and

then is analyzed

under uniform loading

condition in ANSYS Software.

Axial displacement and shear stress have been compared with analytical results.

Load is in direction of spring axis and is exerted on the one end of spring and

other end is fixed in X, Y and Z directions. Meshes with different resolutions

are generated to insure grid independence. Element selected for this analysis is

SOLID45. SHELL element does not show stress variation in the course of

diameter. BEAM element represented stress along the length only and doesn't

show other information about stress. SOLID92 is a pyramid element that

increases time of calculations and it has error in nonlinear complex models. Therefore, a cubic SOLID45 element has been

used in the stress analysis. This element is defined by eight nodes having three degrees of freedom at

each node: translations

in nodal x,

y and z directions.

Replacement Steel

Spring with Composite Spring

Steel helical spring has been replaced by three different

composite helical springs including E-glass/Epoxy, Carbon/Epoxy and

Kevlar/Epoxy. The loading conditions are assumed to be static. Spring Shear stress

has been obtained using FEM and has been compared with steel helical spring.

Composite spring properties have been studied with changing fiber angle

relative to spring axial. The element is SOLID 46, which is a layered version

of the 8-nodes structural solid element to model layered thick shell or solids.

The element has three degree of freedom at each node and allows up to 250

different material layers.

A. Composite helical spring weight

Before modeling of composite helical spring, its weight has been

calculated and compared with steel helical spring. Helical spring weight can be

written as:

where, Na is no. of active loops, d

is wire diameter

and p is weight

per unit volume that can be calculated by

where; Vf , pm is fiber volume and its density,

Vm , pf

is resin volume and its density.

Results

for different percentage of fiber have been shown in Table below:

Compared to steel helical spring, Composite helical spring has

been found to have lesser weight. Also it is concluded that changing percentage

of fiber, especially at Carbon/Epoxy composite, does not affect spring weight.

B. Direction of Fiber in Composite Helical Spring

Spring strength must be calculated at fiber along and fiber

vertical direction and can be written as:

where, Ea is

strength of composite helical spring at along of fiber and Em is its strength in vertical direction of fiber.

Angle fiber has been changed so that fiber position has been

considered in direction of loading, perpendicular to loading and at angles of

30 and 45 degree relative to applied loads. In every case, three different

composite helical springs including E-glass/Epoxy, Carbon/Epoxy and

Kevlar/Epoxy have been considered and longitudinal displacement and shear

stress have been calculated to analyze the effect of spring material upon

spring behaviour. Longitudinal displacement under the effect of fiber angle has

been shown in Fig. below :

Spring has the least longitudinal displacement

when fiber position has been considered to be in direction of loading. With

changing fiber angle, spring longitudinal displacement increases so that it

reaches the greatest value when fiber position has been considered to be

perpendicular to loading. Also, it shows that E-glass/epoxy composite helical

spring has the most flexibility and Carbon/Epoxy composite helical spring has

the least displacement.

Shear stress under effect of fiber angle has been

shown in Fig. below:

Spring has the most Shear stress when fiber

position has been considered to be in direction of loading. With changing fiber

angle, Shear stress reduces so that it reaches the least value when fiber

position has been considered to be perpendicular to loading.

Factors of safety under the effect of applied loads have been

calculated with changing fiber angles. Results have been presented graphically in

Figure below:

Fig. shows that for a composite helical spring, the most safety

factor under the effect of applied loads is related to case that fiber position

has been considered to be perpendicular to loading. Also, Carbon/Epoxy

composite helical spring has more safety factor at any fiber angle in

comparison with other composite helical springs. Therefore, that composite

helical spring is more suitable at this aspect.

Conclusion

In this paper, a helical steel spring has been replaced by three different

composite helical springs. Numerical

results have been compared with theoretical results and found to be in good

agreement. Compared to steel spring, the composite helical spring has been

found to have lesser stress and has the most value when fiber position has been

considered to be in direction of loading. Weight of spring has been reduced and

has been shown that changing percentage of fiber, especially at Carbon/Epoxy

composite, does not affect spring weight. Longitudinal displacement in

composite helical spring is more than that of steel helical spring and has the

least value when fiber position has been considered to be in direction of

loading. The most safety factor is related to case that fiber position has been

considered to be perpendicular to loading and it is for Carbon/Epoxy composite

helical spring.